Introducing Advanced Copper Wire Nugget Plant Technology in India

HYSAN, in strategic collaboration with Sanritsu Machinery, Japan, proudly introduces the Copper Nugget Plant in India — a next-generation solution for efficient and sustainable copper wire recycling.

With decades of Japanese engineering excellence and extensive R&D in copper wire recycling systems, Sanritsu Machinery has developed world- class technology designed for maximum recovery efficiency and material purity. Through this collaboration, HYSAN brings this advanced technology to the Indian subcontinent and beyond, reinforcing its commitment to delivering innovation and quality to both domestic and international markets.

The Wet-Type Copper Nugget Plant is designed to achieve 99% pure copper separation with an equivalent level of plastic purity, ensuring high recovery rates, low operational cost, and eco- friendly performance — making it the ideal choice for modern wire recycling facilities.

Our USP's

- 99% Pure Copper Separation – Achieves exceptional metal recovery with minimal contamination.

- Wet-Type Separation System – Ensures high precision in separating copper and plastic fractions.

- Stable and Efficient Operation – Designed for continuous, low-maintenance performance.

- Energy-Efficient Process – Reduced power consumption with optimized system flow.

- Modular Design – Flexible plant configuration for various capacities and material types.

- Japanese Technology, Indian Support – Backed by Sanritsu's R&D expertise and HYSAN's strong service network.

Commitment to the Wire Recycling Industry

HYSAN and Sanritsu Machinery are committed to empowering the Indian and international recycling sectors. This collaboration goes beyond supplying equipment — it is a shared mission to elevate industry standards, promote the circular economy, and equip recyclers with advanced, high-performance tools.

With the Copper Nugget Plant, HYSAN and Sanritsu Machinery are not just offering a machine; they are delivering a smarter, cleaner, and more profitable future for copper wire recycling.

Process:

The Wet Type Copper Nugget Plant is an advanced recycling system designed to recover pure copper from waste wire harnesses and electrical cables through an eco-friendly wet separation method. This technology ensures high recovery efficiency, minimal material loss, and excellent product purity.

Process Flow:

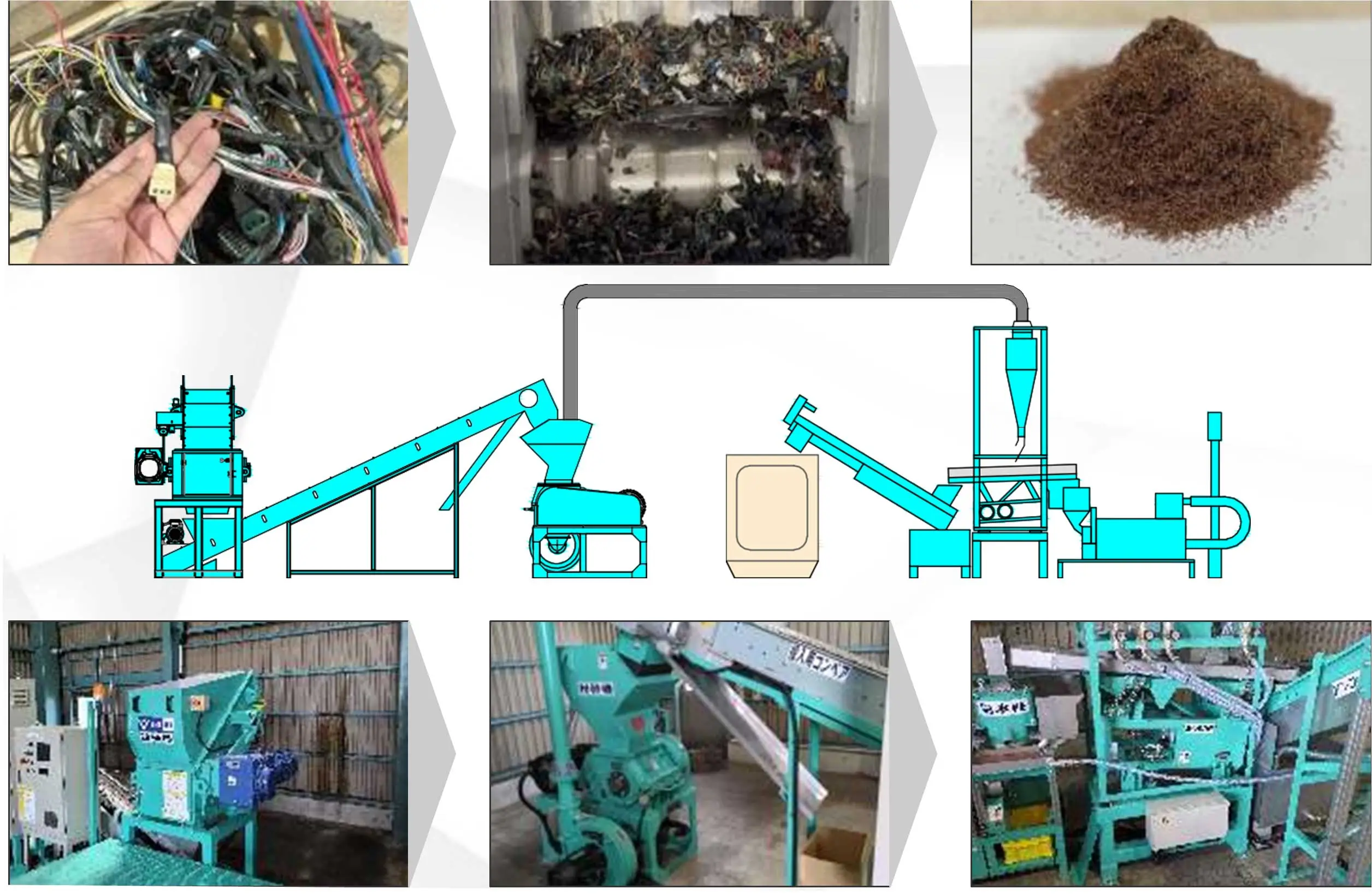

- Raw Material Feeding: Waste wire harnesses or copper cables are fed into the system as the primary raw material.

- Rough & Fine Crushing: The raw wires are passed through a crusher, which cuts and grinds them into smaller pieces. This step helps to liberate copper from plastic insulation and other materials.

- Wet-Type Gravity Concentration: The crushed material then enters a wet-type gravity concentrator, where copper particles are separated from non-metallic impurities using water-based density separation. This method ensures that even fine copper particles are efficiently recovered without oxidation or dust generation.

- Drying with Oven: The recovered copper particles are then dried in an oven to remove moisture, resulting in clean and dry copper suitable for further handling, transport, or melting for reuse.

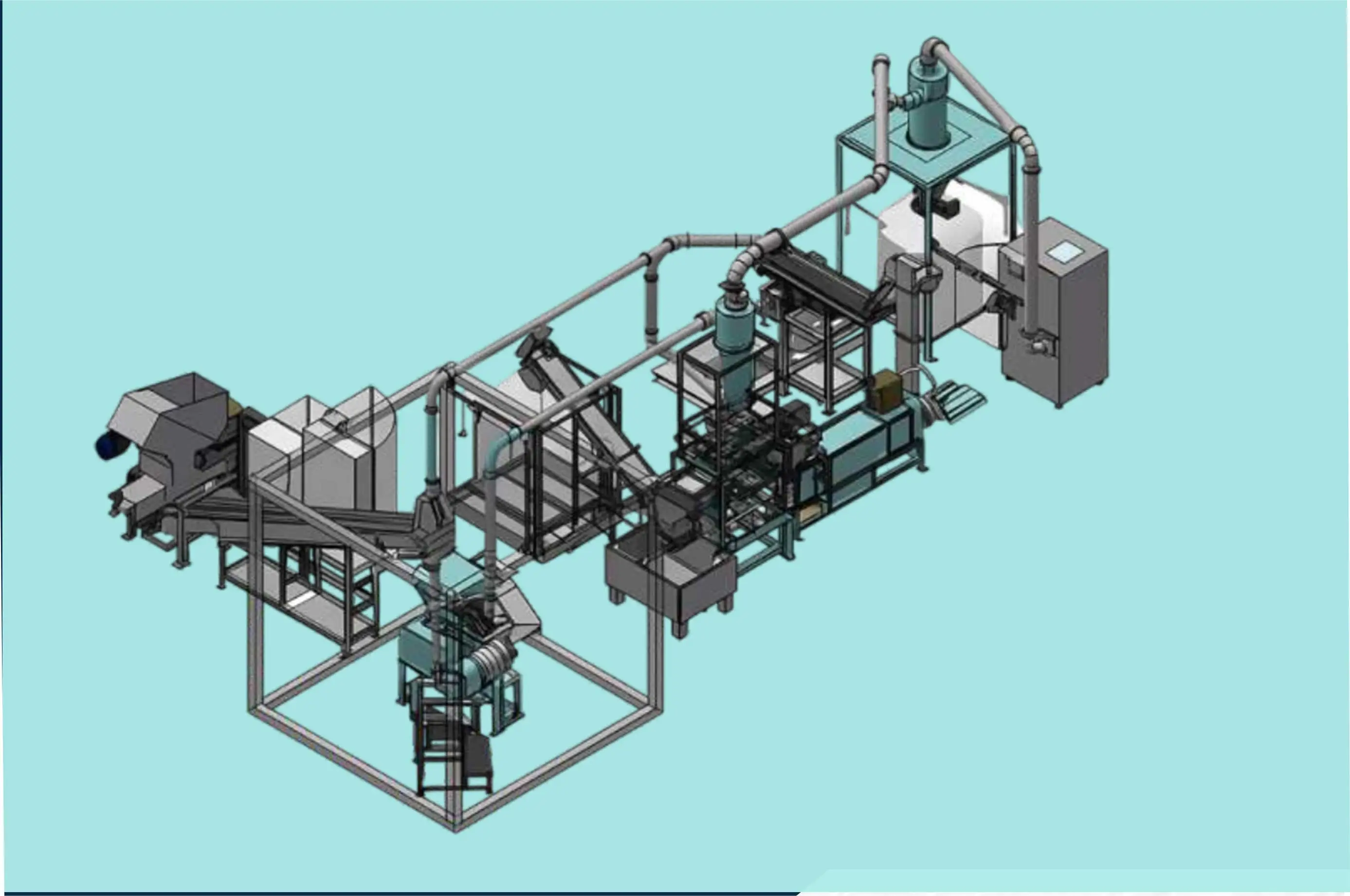

Japan Style Wet Type Nugget Plant

Principle of Wet-Type Gravity Concentration (Thin-Flow Concentration)

Covered wire (low specific gravity) is carried to the low side of an inclined deck by the water flow, while copper wire (high specific gravity) is discharged in the direction of vibration by friction with the bottom surface of the deck, and is separated. In comparison with dry-type gravity concentration, the wet type has excellent separation accuracy (98-99%) and boasts a high copper recovery rate, even with wire harnesses and other fine wires.

Opper Wire Recycling Wet Nugget Plant Models

WN 800: Small Plant with Processing Capacity of 100-200kg / Hr based on raw Materials 0.8 to 1.6 tons / day (8H) 16-32 tons / month (160H)

WN 2400: Medium-Sized Plant With Processing Capacity of 300-600kg / Hr based on raw materials 2.4 to 4.8 tons / day (8H) 48-96 tons / (160H)

WN 3600: Medium- Sized Plant With Raw Material Processing Capacity of 400 to 800 kg / Hr 3.2 to 6.4 tons / day (8H) 64 to 128 tons / (160H)

TECHNICAL SPECIFICATIONS

| Specification | WN-800 | WN-2400 | WN-3600 |

|---|---|---|---|

| Installation Space (In meter) | 10.0 (L) x 6.0 (W) x 3.5 (H) | 13.5 (L) x 9.0 (W) x 5.0 (H) | 13.5 (L) x 9.0 (W) x 5.0 (H) |

| Power Source | 3-phase, 415 V, 30 kW | 3-phase, 415 V, 80 kW | 3-phase, 415 V, 110 kW |

| Throughput | 100-200 kg/hour (gross) | 300-600 kg/hour | 400-800 kg/hour |

| Target Size (Wire Ø) | 20 mm | 30 mm | 30 mm |

OPTIONAL EQUIPMENTS:

- Vibratory Screens (for separating big and small copper nuggets).

- Pulse Type Dust Collector

- PE and PVC Separator

- In feed Conveyor for Rough Crusher

- Power Crusher